Bespoke Custom Rotational Moulding Services

Tanks UK provides a bespoke custom rotational moulding service including in-house welded steel tooling design and plastic rotational moulding manufacturing.

While we specialise in conical tank manufacturing, we service a variety of industries and sectors both across the UK and globally.

Rotational Moulding Tooling Design

We create your rotational moulding tooling design to spec and can provide either stand-alone one-off prototypes to large-scale production volumes.

Our Clients

Our client portfolio includes Tanks Direct, Lister Petter, Carpscope, BOP Box and our own Tanks UK Conical Tank product range.

Custom Products for a Variety Of Sectors

Tanks UK offer custom mould design and in-house built tooling production for quality engineered plastic and steel parts.

We also run a steel fabrication shop, and are thus able to fabricate bespoke steel tanks and products to your personal requirement.

We service a range of customers within a variety of sectors that include:

Oil, Petrol, Diesel & Fuel Tanks

- Plastic Drums

- Plastic Containers

- Plastic Conical Tanks

- Plastic Ethanol Containers

- Plastic Biodiesel Production Tanks

- Plastic Biofuel Storage

- Jerry Cans

- HGV Fuel Tanks

- Custom Fuel Tanks

Agricultural & Livestock Feeders

- Plastic Water Troughs

- Drinkers

- Plastic Gate/Ground Feeders

- Meal Bins

- Plastic Footbaths

- Dipping Tubs

- Plastic Wheelbarrows

- Buckets

- Plastic Grit Bins

- Bespoke Livestock Feeders

Hazardous Chemical Industry

- Plastic Mixing Tanks

- Chemistry Storage

- Hazardous Chemical Containers

- Chemical Storage Cabinets

- Plastic Flammable Liquid Storage

- Waste Containers

- Custom Plastic Chemical Tanks

Water Storage & Treatment Vats

- Plastic Water Filtration Tanks

- Plastic Waste Water Containers

- Plastic Liquid Storage

- Poly Water Storage Tanks

- Rainwater Bins

- Large Water Containers

- Water Holding Tanks

- Bespoke Water Tanks

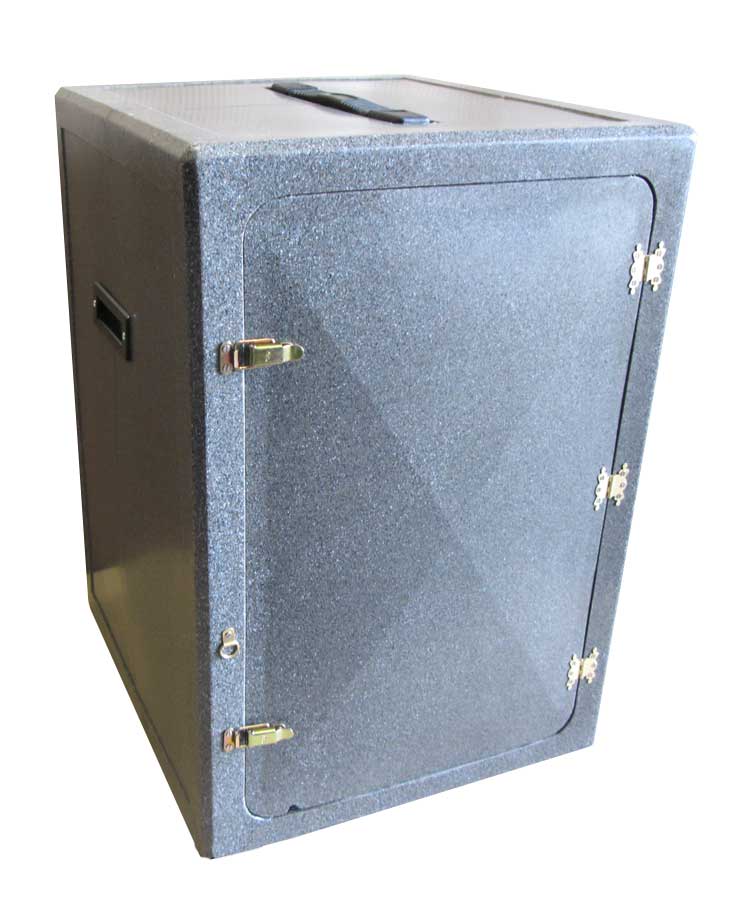

Transportation & Shipping Tanks

- Plastic Water Transport Tanks

- Shipping Boxes

- Septic Cisterns

- Plastic Storage Tubs

- Plastic Carrying Cases

- Shipping Cases

- Small Plastic Shipping Containers

- Custom Shipping Boxes

Plastic Storage Containers

- Plastic Storage Bins

- Large Plastic Storage Boxes with Lids

- Plastic Storage Containers

- Plastic Storage Baskets

- Storage Cabinets

- Plastic Drawers

- Heavy Duty Storage

- Flower Pots

- Bespoke Storage Containers

Our Moulding Process

Our rotational moulding is a three-stage, no-pressure, plastic moulding process.

During the heating stage, the mould slowly rotates in two planes (bi-axial rotation). Heat transfer causes the plastic charge inside the mould to melt and uniformly coat the interior of the mould.

During the second stage, the mould moves to the cooling station where it is cooled by air and/or water spray.

In the final load/unload stage, the part is removed from the mould and a new charge of material is loaded into the mould.

Our 2 gas heated rotational ovens are able to house toolings up to 6m2, with average process time of just 30 mins.

We’re With You

1. Consultation

Our Technical consultancy for rotational moulding service covers the material choice, thickness, stiffness, flexibility and longevity of the finished article and offer advice on how best to achieve the desired output.

2. Design

Our Design consultancy for rotational moulding service covers the appropriateness, shape, size, functionality and application of the finished article.

3. Testing

Whether it’s an on-going production or a single run, our Finishing and Quality team review every single product that enters and leaves our facilities to ensure that they’re manufactured to the highest of standards.

4. Tooling

Typically utilising our in-house Steel Fabrication Workshop, we then create the required custom manufactured tooling which will act as the mould during the rotational moulding process.

5. Manufacturing

We then start the plastic rotational moulding process to form the typical body of the product. Which is then taken to finishing, where any specific features or accessories are then incorporated to produce a quality finished article.

6. Delivery

Whether delivering to you or your customers directly, we strive to ensure that the product reaches you as expected.

Why Choose Tanks UK

Innovative Spirit

We are adept at taking your idea and using our experience and innovative techniques to deliver a fantastic final product.

Customer Focused

We work closely with our customers to ensure that their needs are put first, whilst always striving to meet and exceed their expectations.

High Quality

We offer a high quality service from conception and design through production, customer service, quality assurance, and delivery.